In 3D printing, the choice of slicing software can significantly impact the quality and customization of your prints. SuperSlicer and PrusaSlicer, both are introduced by the original Slic3r. They offer advanced tools made for people looking for precision and control. SuperSlicer is a fork of PrusaSlicer. It enhances upon its predecessor with advanced features.

This article will walk you through the similarities and differences between these two popular slicers. It’ll show you how each software helps its users in 3D printing.

Similarities between SuperSlicer and PrusaSlicer

1. Open-Source Foundation

Both SuperSlicer and PrusaSlicer are built upon open source software principles. They inherit their lineage from the original Slic3r project. This foundation fosters a collaborative environment where developers and users alike contribute to improving the software. It also ensures transparency with code accessible for modification as needed.

2. Compatibility

Both slicers support a broad spectrum of 3D printers. They are perfect choices for users regardless of their hardware setup. They offer compatibility with popular printer models and firmware configurations. They have allowed users to work smoothly without compatibility concerns.

3. Slicing Capabilities

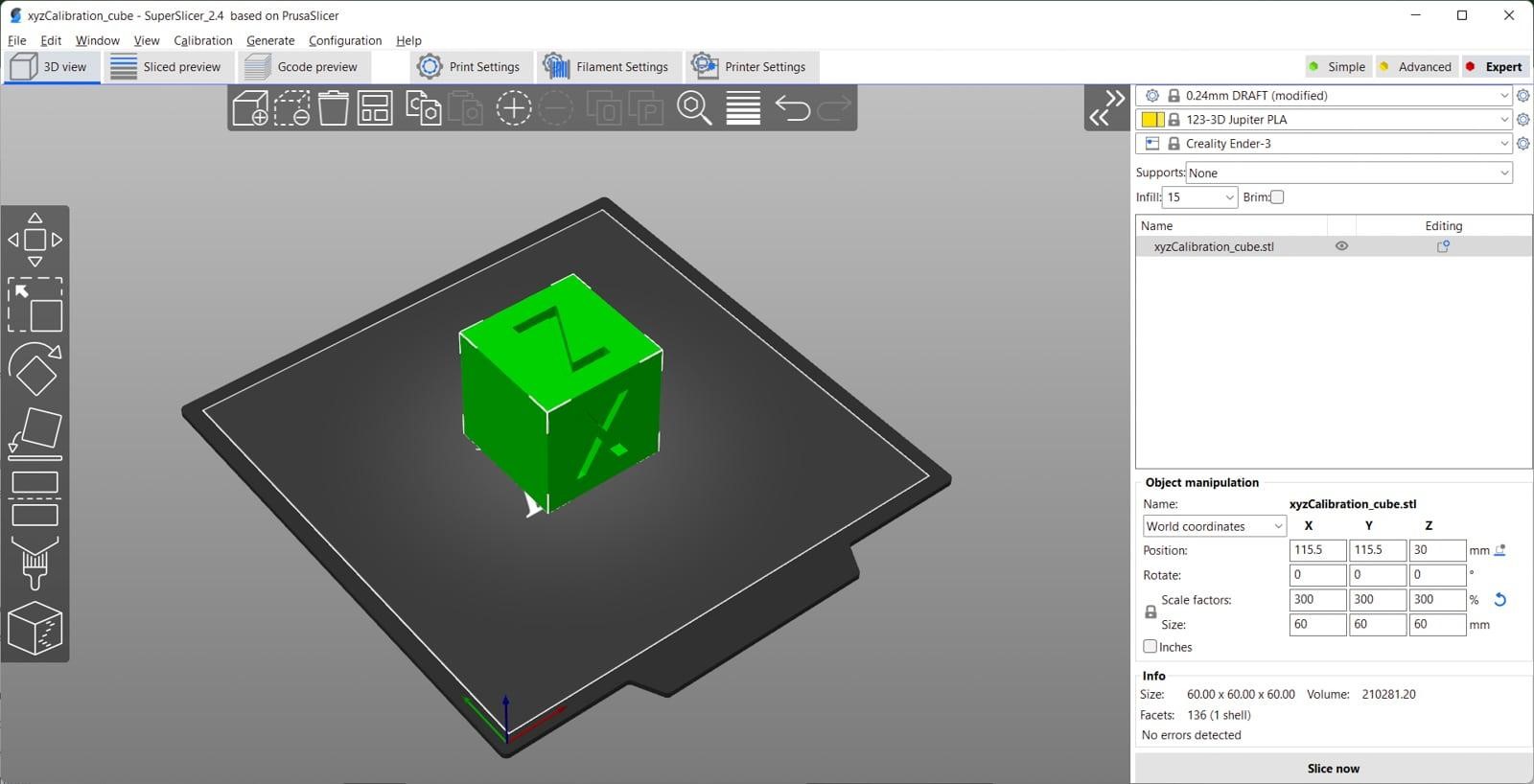

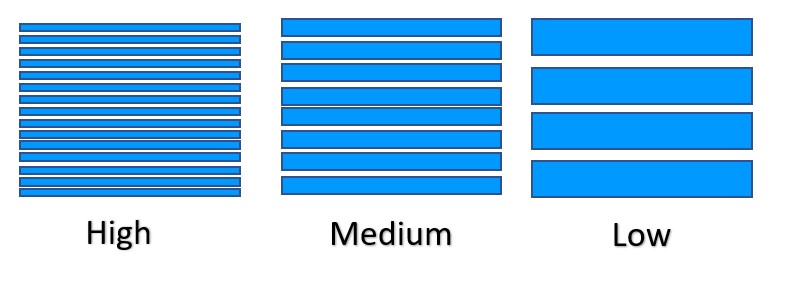

Both slicers provide advanced slicing capabilities that enable users to achieve high quality prints. They support features like variable layer heights, adaptive layering, and customizable supports. The slicers help users to optimize print settings based on specific geometries and material properties. Additionally, they offer options for infill patterns, shell thickness, and print speed adjustments.

4. Community Support

Both SuperSlicer and PrusaSlicer have active and supportive user communities. Users frequently share tips, troubleshooting advice, and custom profiles. This improves the overall user experience.

5. Regular Updates and Improvement

Continued development is a hallmark of both SuperSlicer and PrusaSlicer. Regular updates introduce new features, performance enhancements, and bug fixes. These ensure that users have access to the latest advancements in slicing technology. This commitment to ongoing improvement reflects the developers’ responsiveness to user feedback and the evolving needs of the 3D printing community.

6. Customization Options

Both slicers offer extensive customization options that allow users to tailor print settings to their specific preferences and requirements. They provide fine grained control over parameters such as print speed, temperature settings, and support structures. They let users optimize prints for different materials and geometries.

7. Multi-material and Multi-color Printing

Both slicers support multi-material and multi-color printing. However, this comes with varying degrees of complexity and support for different printers. Both provide tools for managing color transitions and material switching.

Differences between SuperSlicer and PrusaSlicer

1. Development and Support

SuperSlicer is a community driven fork of PrusaSlicer. It originated from the desire to expand upon the capabilities and features of the original PrusaSlicer. While both slicers are open source and benefit from community contributions, their development trajectories and support structures differ.

PrusaSlicer follows a more structured development cycle with regular updates and official support channels. In contrast, SuperSlicer relies on community driven updates and contributions. This can lead to more rapid feature integrations but may vary in stability and official support documentation.

2. User Interface and Experience

One of the notable differences between SuperSlicer and PrusaSlicer lies in their user interfaces (UIs) and user experiences (UX). PrusaSlicer maintains a UI design that is consistent with other Prusa Research products. It is characterized by a clean layout with intuitive controls. The UI emphasizes ease of use and is accessible for both beginners and advanced users without too much complexity.

On the other hand, SuperSlicer has evolved to offer a more customizable and feature rich UI. It provides enhanced configurability options. It has allowed users to tailor the interface to their specific preferences and workflow requirements. This includes customizable toolbars, panel layouts, and additional display options.

3. Advanced Slicing Features

Both SuperSlicer and PrusaSlicer excel in offering advanced slicing features that enhance print quality and customization. However, the depth and breadth of these features differ between the two slicers. PrusaSlicer typically integrates features that are meticulously tested and optimized for Prusa 3D printers. The features include advanced algorithms for supports, variable layer heights, and filament specific settings.

SuperSlicer often introduces experimental or advanced features sooner than PrusaSlicer. These may include cutting edge slicing algorithms, experimental print modes, or enhanced customization options not yet integrated into PrusaSlicer’s stable releases. Users looking to experiment with latest technologies may find it appealing.

4. Customization and Extensibility

SuperSlicer places a strong emphasis on customization and extensibility compared to PrusaSlicer. It offers a broader range of customization options and allows users to fine tune slicing parameters, interface layouts, and even integrate plugins and custom scripts more extensively. This flexibility draws advanced users, developers, and those who benefit from deep customization capabilities.

In contrast, while PrusaSlicer supports some level of customization through profiles and settings adjustments, its focus is on providing a streamlined user experience that prioritizes ease of use and reliability. The customization options in PrusaSlicer are typically geared towards optimizing prints for Prusa hardware and ensuring compatibility with their ecosystem of products and materials.

5. Multi-material and Multi-color Printing Support

Both SuperSlicer and PrusaSlicer support multi-material and multi-color printing, but the implementation and ease of use can differ. PrusaSlicer integrates high end tools for managing multi-material prints. It provides smooth transitions, purging volumes, and color assignment controls. These features are optimized for Prusa’s own multi-material upgrade kits and provide an easy workflow for users aiming to create complex, multi-component prints.

SuperSlicer may incorporate experimental features or alternative approaches to multi-material printing management. This can include different algorithms for managing tool changes, color mixing strategies, or unique approaches to handling transitions between materials. These features may require more manual setup or troubleshooting compared to PrusaSlicer’s more integrated solutions.

6. Community and Support Ecosystem

PrusaSlicer benefits from a well established support ecosystem maintained by Prusa Research. It includes official documentation, user forums, and direct technical support channels. This structured support network ensures users have access to reliable resources, troubleshooting guides, and community driven solutions for common issues.

SuperSlicer relies heavily on its user community for support and documentation. While it benefits from active contributions and rapid feature developments from community members, the availability and consistency of support resources may vary compared to PrusaSlicer’s more centralized support infrastructure.

7. Stability and Release Cycle

PrusaSlicer maintains a stable release cycle with periodic updates that undergo rigorous testing to ensure stability and compatibility with Prusa hardware configurations. These updates typically focus on refining existing features, optimizing performance, and introducing new functionalities in a controlled manner. This stability makes PrusaSlicer a reliable choice for users prioritizing consistent performance and compatibility with Prusa printers.

SuperSlicer may have a more agile release cycle with updates and new features introduced more frequently. While this allows for faster integration of community driven innovations and experimental features, it may also result in occasional stability issues or compatibility challenges, especially with less common printer configurations or materials.

8. Target Audience and Use Cases

Overall, the differences between SuperSlicer and PrusaSlicer often align with their respective target audiences and primary use cases within the 3D printing community. PrusaSlicer appeals to users looking for a reliable, user friendly slicer optimized for Prusa hardware. It is well suited for both beginners and experienced users looking for a simple slicing solution with top notch multi-material support and a focus on print quality.

SuperSlicer, on the other hand, serves users who value customization, experimental features, and community driven development. It attracts advanced users, developers, and those with specific workflow requirements that benefit from broader compatibility across different printer brands and configurations.

Best 3D Design Software

There are a lot of 3D Design software available that you can use to prepare your dental designs and prepare them for 3D printing and a good example is SelfCAD. SelfCAD is a powerful 3D modeling software that you can use to create 3D models from scratch or edit existing designs and customize them based on your needs.

If the files have issues like unnecessary holes, you can fill them easily using the various tools of the software. After preparing your files, you can then use the in-built online slicer of the software to slice your files and generate the Gcode to send to your 3D printer.

In addition to being easy to use, SelfCAD also comes with many resources to help you get started with ease. There are many interactive tutorials to help you learn by actually creating 3D models. 3D modeling 101 series and 3D modeling for beginners videos on YouTube are also great resources to help you learn how SelfCAD works and how you can use it to create your 3D models.

Conclusion

SuperSlicer and PrusaSlicer, both are descendants of Slic3r. They offer perfect solutions for 3D printing lovers. PrusaSlicer excels in reliability, user friendly design, and integration with Prusa hardware. It is ideal for those prioritizing stability and ease of use. In contrast, SuperSlicer appeals to users who want advanced customization, experimental features, and broader printer compatibility through its community driven development.